Armes Precision » Blog

Precision Machining and Its Impact on Mechanical Assemblies

In the world of manufacturing, mechanical assemblies are the backbone of countless industries, from aerospace to automotive and beyond. These assemblies are much more than a collection of parts—they’re intricate systems where every component must work seamlessly together to deliver reliability, efficiency, and longevity. Precision machining plays a pivotal role in ensuring that these components…

Read articleOptimizing Supply Chains: Machining, Fabrication & Finishing Together

Getting a product from concept to completion efficiently allows companies to respond quickly to market changes. Yet, relying on multiple suppliers for machining, fabrication, and finishing often leads to delays, miscommunication, and increased costs. When various vendors are involved, the risk of supply chain disruption rises, impacting quality and timelines. That’s where Armes Precision steps…

Read articleChallenges in Mechanical Assembly and How to Overcome Them

Mechanical assembly is the backbone of countless industries, from aerospace to automation. It’s the process of combining individual components into a cohesive system that must perform with precision and reliability. However, this complex process isn’t without its challenges. Issues like inconsistent tolerances, material incompatibility, and environmental factors can disrupt production and compromise performance. Whether you’re…

Read articleWhat Are the Different Types of Painting

Painting metal surfaces is more than just an aesthetic choice. It’s a vital step in protecting and extending the life of your components. With various types of paints available, each suited for different conditions and requirements, it can be challenging to determine which method is best for your specific needs. Understanding the options available and…

Read articleWhat Are the Different Types of Anodizing

Anodizing increases durability, corrosion resistance, and aesthetic appeal. It enhances the wear resistance of aerospace components or adds a vibrant color finish to consumer electronics. Understanding the appropriate use of anodizing can help you decide if it’s right for your manufacturing project. What is Anodizing? Anodizing is an electrochemical process that enhances the natural oxide…

Read articleWhat to Look for in a Conveyor Components Maker

Choosing the right conveyor components is a critical decision that can significantly impact your operation’s efficiency and reliability. Conveyor systems may seem straightforward, but they are complex machines with numerous moving parts that have to work together reliably with minimal downtime. This makes it challenging for conveyor builders and operators to find the right manufacturer…

Read articleChallenges with Welding Titanium

Titanium is a metal that’s widely used in the aerospace, industrial automotive, and defense industries. For high-end manufacturing businesses working on a project, it’s a solid metal for projects because of its good qualities. More specifically, its unique ability to resist corrosion and strength-to-weight ratio. It’s no surprise that the metal ranks tall on project manager’s load…

Read articleNuclear Energy: A Sustainable Power Source for Growing Data Centers

In today’s digital age, data centers are the backbone of our connected world. From cloud computing to streaming services, the demand for data processing and storage is surging. However, powering these data centers sustainably is a challenge. One needs to look no further than in Virginia where a new power transmission project will keep coal…

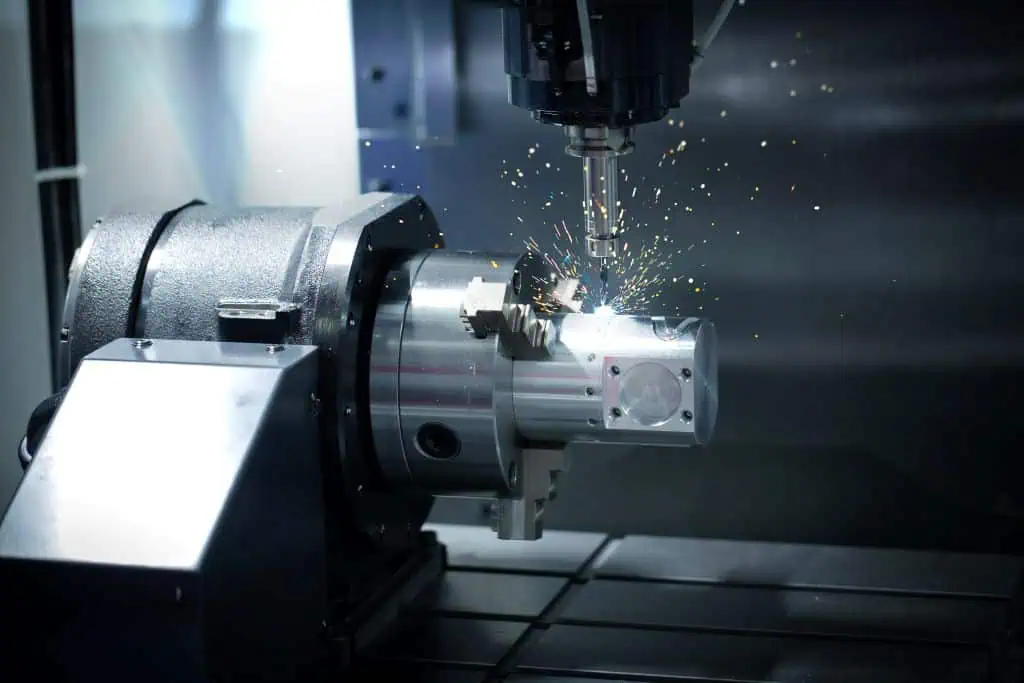

Read articleCNC Milling vs. Laser Cutting: Which Is Better?

CNC milling and laser cutting are precision engineering techniques that are pivotal in manufacturing complex or high-tolerance components. Both methods have unique strengths and applications and are used extensively in industries ranging from medical and automotive to aerospace and woodworking. While both CNC milling and laser cutting are integral to modern manufacturing, they employ distinctly…

Read articleThe Crucial Role of Quality Management Systems in Contract Manufacturing: Unpacking ISO 9001 and AS9100 Certifications

In today’s fast-moving, high-precision, and highly unforgiving world of contract manufacturing, quality is not just imperative—excellence in Quality Management Systems (QMS) based on standards such as ISO 9001 or AS9100 is an absolute necessity. This is especially true for sectors like metal fabrication, machine shops, and those involving complex processes such as CNC milling and…

Read articleUnlocking Complex Assemblies: The Power of Combining Precision Machining with Metal Fabrication

In the intricate dance of modern manufacturing, two processes stand out for their ability to create the complex, high-quality components that industries demand: precision machining and metal fabrication. On their own, each offers a unique set of capabilities and advantages. However, when combined, they unlock a level of efficiency, versatility, and quality that is greater…

Read articleOptimizing Partnership Outcomes: A Guide for Industrial Automation Firms to Choose the Ideal Metal Fabrication Company

When evaluating a metal fabricator, it’s best to use standard evaluation metrics like quality, reliability, and efficiency. Fairly commonplace attributes you would use for most if not all suppliers. Attributes like those listed by MachineDesign are helpful but lack nuance when taking the point of view of a particular business sector like industrial automation. We…

Read articleReshoring Impact: Opportunities and Challenges for U.S. Machining and Metal Fabrication Contract Manufacturers

In this new move toward reshoring or bringing some of their offshore production back into their home countries due to reasons associated with global supply chain disruptions, geopolitical tensions, and changed consumer demands, companies are realigning strategies across different sectors. This brings a mélange of forces such as economic and logistical challenges emerging from the…

Read articleSynergizing CAD and CAM for Efficient Custom Manufacturing

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) integration is an enabler for companies working with assistive technologies to be able to convert creative ideas into physical products. It is crucial for firms that involve the production of custom adaptive technology solutions to create a synergy that will enable them to produce specialized products such as…

Read articleShipyard Readiness: US-China Tensions and Strategic Preparedness

Chinese shipyards are now in the best times and prepared to back a long war in the Indo-Pacific. The fact that they are ready to build at wartime rates seems to be an indicator of the high level of preparedness for a long war. In contrast, the state of the shipbuilding industry in the…

Read articleMastering the Art of Stacking Welds: Overcoming Challenges for Superior Joint Integrity

Armes Precision, a leading machining, welding, and complex part manufacturing company based in Lynchburg, Virginia, recently tackled a highly challenging fabrication project involving a large steel apparatus composed of 8’ x 2’ steel tubes, 7’ x 7’ steel vertical posts, and 1 ¼-inch steel plates. Due to the sheer size of the apparatus, manual maneuverability…

Read articleChoosing the Right Welding Techniques for Fabrication Projects

Introduction We undertake a tremendously wide variety of precision welding projects here at Armes Precision of Lynchburg, Virginia, and selecting the appropriate welding technique is crucial for achieving high-quality, durable results. Different fabrication projects require specific welding methods to ensure structural integrity, aesthetic appeal, and efficient production.As a leading machining, welding, sheet metal forming, and…

Read articleThe Benefits of Working with 2-Axis, 3-Axis, and 4-Axis Milling Machines: A Comprehensive Overview by Expert Machinists

Introduction At Armes Precision, our multi-specialty manufacturing and machining company has been using a variety of multi-axis milling machines ever since our company was founded in Lynchburg, Virginia, in 1995. While the cost of mixed-asset types[1] might be expensive compared to uniform-asset types, the diversity in capability is well worth the cost. Milling machines play…

Read article