When evaluating a metal fabricator, it’s best to use standard evaluation metrics like quality, reliability, and efficiency. Fairly commonplace attributes you would use for most if not all suppliers. Attributes like those listed by MachineDesign are helpful but lack nuance when taking the point of view of a particular business sector like industrial automation. We have found in our 29 years of manufacturing experience that there are more specific winning traits to focus on when it pertains to industrial automation.

By carefully evaluating these characteristics, you can select the right metal fabricator for your industrial automation needs, ensuring a successful partnership and the delivery of high-quality, customized components and solutions.

Automation Experience & Technical Competence

Firstly, and this may seem obvious, but look for a metal fabricator and machining company that has experience in the actual field of industrial automation. Have they created complex assemblies such as those that require machined, fabricated, and purchased components which need to be assembled before finding their way onsite of a customer? Many industrial automation systems are highly customized production lines that require a wide range of part sizes mechanically assembled or welded together. This requires technical expertise in multiple disciplines – not simply cutting and bending.

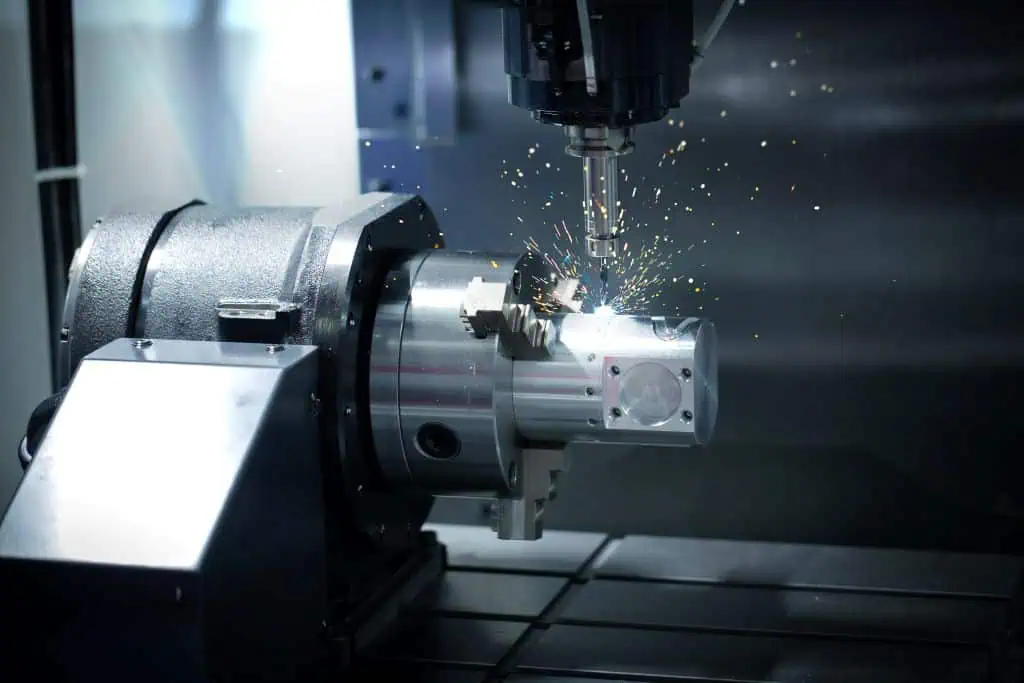

Analyze the technical competence of the manufacturer, which includes the ability to work on several metal types, the range of fabrication skills, and the machining and fabrication processes that are suitable for industrial automation applications. They should have an array of equipment and technology that range from CNC mills to laser cutters to rollers and welding tools. This allows them to be able to efficiently service some of the most intricate projects.

Speed, Quality, and Capacity

Speed often compromises quality. So even when the requirements are on a tight deadline, you need to find a manufacturer who keeps up the highest standards of quality during the production process. Make sure the supplier has and follows a quality management system. Look for relevant certifications, such as ISO 9001 and AS9100, to assure that the products are reliable and consistent. Having a certification does not guarantee perfection. It does show that the supplier is focused on and has a system in place for doing better.

Take into consideration the production capacity and scalability that the fabricator and job shop can offer. Industrial automation companies float between the highly custom production lines and repeatable cell installs. A good shop should be suitable for your current needs, but a great shop should support current needs as well as foresighted needs. Their resources must be enough to withstand infrequent large-volume orders (think repeatable cells), even under strict schedules, and still be able to maintain the same quality, as well as the same delivery times. At Armes Precision we determine if the production volume is large enough and consistent enough to warrant a dedicated production line. We then assess our capacity and create a plan to produce any custom one-offs by using a combination of in-house and subcontractors.

Systems, Subsystems, & Sub-subsytems

Automation systems for manufacturers often require custom subsystems which need to be built according to specific requirements. Because of the level of customization and the requirement for last minute alterations, it is key to find a metal fabricator who is willing to work hand in hand with your engineering team to understand fully what your requirements and specifications are. This means that good communication and collaboration are the keys to a successful partnership with your fabricator. Make sure the supplier you work with offers open lines of communication. They need to pay attention to your questions, feedback, and project updates from the beginning to delivery of the assembly.

Value vs Price

Lastly, value should be a more important factor than price. A cheap part that must be remade or fails because of poor quality becomes an expensive headache in the long run, which affects your reputation and your bottom line. Other intangible elements that are particular to your business factor into value. Do you have a fluid project plan, i.e., are your project dates highly variable? If so, you need a supplier with the flexibility to shift production schedules and hold inventory.

Ask them for their case studies, testimonials, and clients’ references to check their reputation and their value to their customers. Find out not what the manufacturer did when the project was well defined and had plenty of lead time, but when there was a significant time crunch. Did they deliver when they were needed most? How is the quality of their work under that constraint? Did they keep their customers abreast of the project? Companies talk about “commitment” … most of the time it is just a marketing talking point.

At Armes Precision of Lynchburg, Virginia, we have been working with industrial automation companies for over 20 years in the areas such as conveyors, palletizers, canning systems, bottling systems, filling systems, case pickers, robot cells and other such industrial automation systems. Our machining and metal fabrication capabilities along with our welding and assembly expertise has made us a leading partner for those design and engineering firms building automation systems.

#IndustrialAutomation #TechnicalExpertise #QualityManagement #Scalability #Collaboration #Value