What we do

Custom Solutions

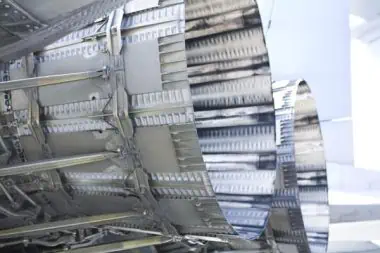

We specialize in providing customized solutions for the commercial aerospace and defense industry, helping our clients to optimize their processes and maximize efficiency

High-Quality Products

Our commitment to quality ensures that every component we produce for the aerospace and defense industry meets the highest standards

of quality and reliability.

Experience and Expertise

Our experienced team has the expertise and

knowledge to handle even the most complex

aerospace and defense projects, from simple

components to large and intricate assemblies.

Advanced Technology

We use the latest technology and equipment to

manufacture our products, ensuring precise and efficient production that meets the unique needs of the aerospace and defense industry.

Why Armes Precision ...

- Tailored assembly for unique requirements.

- ITAR Registered

- Commitment to quality and reliability

- Exceptional manufacturing for critical applications.

- Precision machining for low tolerance applications

- Professional welding for crucial applications

What sets us apart

Mission-Critical Manufacturing: Our Aerospace & Defense Process

ITAR Registered. AS9100D Certified. NAVSEA-Capable.

At Armes Precision, we specialize in precision machining and fabrication for aerospace and defense applications where failure is not an option. Our process is built around security, compliance, and performance—supporting classified, export-controlled, and mission-critical programs.

1. Secure Quote Submission & Feasibility Review

Technical data packages (TDPs), 3D models, and drawings are submitted through our PreVeil platform, which provides end-to-end encrypted CUI handling and secure file storage – ensuring full alignment with DFARS and NIST 800-171 compliance requirements.

Our sales engineering team quickly reviews:

Manufacturability and complexity

Material availability and lead times

Compliance with specifications (e.g., MIL-SPEC, NAVSEA drawings, AWS D1.6)

2. Detailed Quotation with Compliance Clauses

Quotes are typically returned within 1–3 business days for simple parts and include:

Firm-fixed pricing or T&M structure

Estimated lead times

Flow-downs for ITAR, DFARS, and program-specific clauses

Anticipated certification deliverables (AS9100D, FAI, weld procedures, etc.)

3. Contract Award & Work Authorization

Once the PO is received and export control requirements are verified, jobs are loaded into our Advanced Planning & Scheduling system (MxAPS) and tracked through our Manufacturing Execution System (MES) to ensure:

Full traceability

Load-balanced scheduling

Traveler-based process control

4. CNC Programming & First Article Prep

Our internal programming team uses FeatureCAM to generate precise, optimized toolpaths for multi-axis CNC equipment. Each program is paired with:

Setup sheets and fixturing plans

In-process inspection instructions

First Article Inspection (FAI) documentation per AS9102

5. Controlled Production & Traceability

Parts are machined, fabricated, and welded under controlled conditions:

Raw material traceability through all manufacturing stages

Certified welding to AWS D1.6 and NAVSEA S8 structural codes

NDT performed by technicians trained per NAVSEA Tech Pub 271

6. Final Inspection & Documentation

Our Quality Management System, certified to AS9100D and ISO 9001, ensures:

Dimensional and visual inspection reports

CoCs, material certs, and NDT documentation

Secure archiving and record retention for government audit readiness

7. Secure Packaging & Delivery

Parts are preserved, packaged, and labeled in accordance with MIL-STD-2073 or customer-specific guidelines. We ship to DoD depots, defense primes, and integrators—on time and with full documentation.