Painting metal surfaces is more than just an aesthetic choice. It’s a vital step in protecting and extending the life of your components. With various types of paints available, each suited for different conditions and requirements, it can be challenging to determine which method is best for your specific needs. Understanding the options available and their unique benefits can help you make an informed decision, ensuring optimal performance and durability for your project.

What Are the Different Types of Painting?

Painting metal surfaces provides protection, longevity, and performance. Each paint type has its unique features and benefits:

Alkyd Paints

Alkyd paints are oil-based and versatile, making them popular for many applications. These paints serve as primers, undercoats, and topcoats. They provide moderate protection with a high gloss finish. However, they have poor color retention and slow drying times. They also don’t adhere well to galvanized surfaces.

Acrylic Paints

Acrylic paints are either water- or solvent-based and are known for their durability. They offer excellent color and gloss retention. Due to their superior adhesion properties, acrylic paints are particularly suited for architectural and outdoor use. Despite being more expensive, their long-lasting nature makes them a worthwhile investment.

Epoxy Paints

Epoxy paints are two-component systems mixed with a hardener. Compared to alkyd paints, they provide better corrosion protection and heat resistance. Though they excel in protection, their poor color retention often necessitates an additional polyurethane coat. Due to their higher cost but superior performance, these paints are ideal for moderate corrosive environments.

Zinc-Based Primers

Zinc-based primers offer the highest level of corrosion protection through sacrificial corrosion. These primers are commonly used in marine and highly corrosive environments where hot dip galvanization isn’t feasible. But beware: applying these primers too thick can lead to cracking.

Polyurethane Paints

Polyurethane paints boast exceptional chemical resistance, among other perks. They provide clarity, high gloss, hardness, flexibility, and abrasion resistance. Often used as topcoats over epoxy paints for enhanced color retention and gloss, they are a premium option for demanding applications.

Powder Coating vs Paint

When it comes to finishing metal surfaces, powder coating, and traditional paint have unique advantages. Understanding these differences can help you make an informed decision about your project.

Powder Coating

Powder coating involves applying a dry powder that is cured in an oven. This method offers superior corrosion and wear resistance. It’s cleaner, faster, more durable, and less expensive in the long run. However, powder coating requires specialized equipment, making it difficult to remove once applied. Some types may also lack UV resistance.

Traditional Paint

Traditional paint is usually applied via spray painting and is air-dried. This method is affordable and suitable for parts that cannot be heated. It offers a thin finish ideal for low-volume runs and allows for precise color matching. On the downside, traditional paint is less durable than powder coating and doesn’t offer the same level of protection against elements like corrosion.

While both methods have their merits, choosing the right one depends on your specific needs and constraints. For instance, if you require a durable finish with excellent corrosion resistance, powder coating might be the way to go. Conversely, if you’re looking for an affordable solution with customizable colors for smaller projects, traditional paint could be more suitable.

Other Coating Techniques

Beyond powder coating and traditional paint, several other coating methods can enhance the durability and appearance of metal surfaces. Each technique has its unique benefits, making them suitable for different applications.

Anodizing

Anodizing is an electrochemical process that creates an oxide layer on aluminum or steel. This method improves corrosion protection, provides electrical insulation, and reduces friction. While anodizing offers excellent durability, it can be more expensive due to the specialized equipment and chemicals required.

Galvanization

Galvanization involves coating metal with zinc using the hot-dip method. This technique provides outstanding corrosion protection and enhances the appearance of metal parts. However, the zinc layer can become brittle and porous over time, and the process is relatively costly compared to other methods.

Plating

Plating includes both electroplating and electroless plating techniques. Electroplating uses an electrical current to deposit a metal layer, while electroless plating relies on an auto-catalytic reduction of metal ions. Plating is cost-effective and often used in conjunction with other finishes. However, the thin layer can be prone to scratches and limited UV resistance.

E-Coating

E-coating involves electrically applying paint by dipping parts into a paint bath and curing them in an oven. This method provides good corrosion protection but results in a thinner finish than powder coating.

Each coating technique has its strengths and weaknesses, making them suitable for various applications depending on your specific requirements.

Preparing Materials for Paint

Proper preparation is crucial for achieving a high-quality paint finish on metal surfaces. Different metals require specific methods to ensure the paint adheres well and lasts long.

Cleaning

The first step in preparing any metal surface is thorough cleaning. Dirt, grease, and other contaminants can prevent paint from adhering properly. Common cleaning methods include:

- Solvent Cleaning: Using solvents like acetone or mineral spirits to remove oils and grease.

- Detergent Cleaning: Washing with water and mild detergents to remove dirt and residues.

- Abrasive Blasting: Using materials like sand or glass beads to clean and roughen the surface.

Surface Treatment

After cleaning, the next step is treating the surface to enhance paint adhesion. This can involve mechanical or chemical processes, depending on the type of metal.

- Mechanical Abrasion: Sanding or grinding the surface to create a rough texture that helps paint adhere better.

- Chemical Etching: Using acids or other chemicals to remove oxides and create a suitable surface profile for painting.

Priming

Applying a primer protects the metal from corrosion and helps the topcoat adhere well. The type of primer used depends on the metal and the environment in which it will be used.

- Zinc-Based Primers: Ideal for steel surfaces exposed to harsh environments.

- Epoxy Primers: Excellent for providing strong adhesion and corrosion resistance on various metals.

- Alkyd Primers: Suitable for general-purpose applications but not recommended for galvanized surfaces.

Special Considerations for Different Metals

Different metals have unique properties that require specific preparation techniques:

- Aluminum: Requires thorough cleaning followed by an etching primer to ensure proper adhesion.

- Stainless Steel: Needs abrasive blasting or chemical etching before applying a suitable primer.

- Copper and Brass: Often require a specialized primer designed for non-ferrous metals to prevent oxidation.

Proper preparation ensures that your painted metal surfaces look great and withstand wear and tear over time.

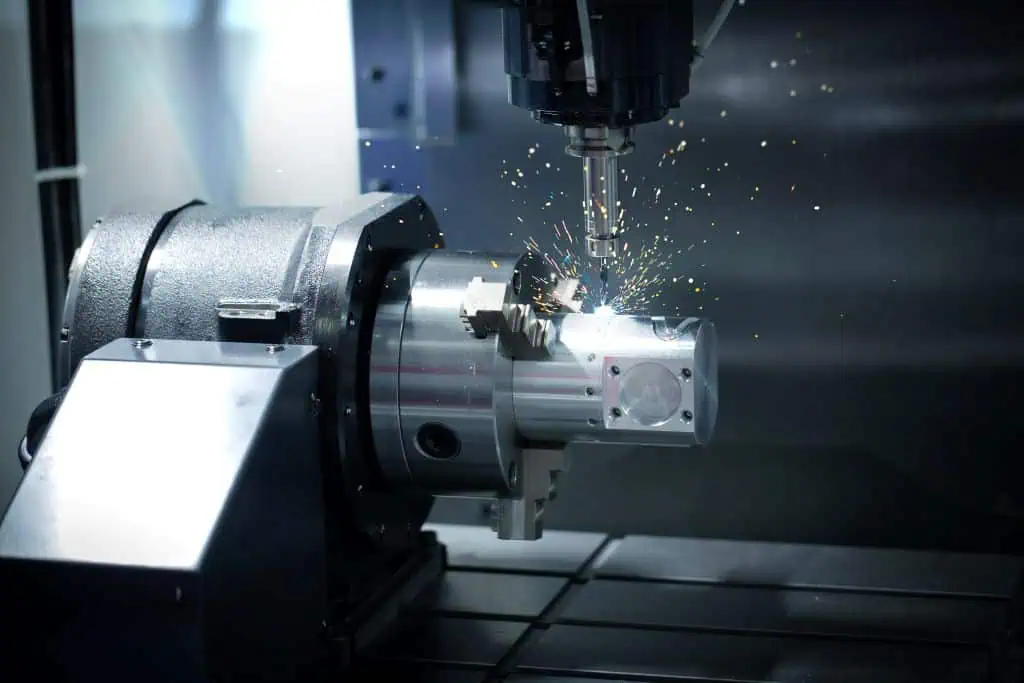

Reliable Metal Fabrication

When it comes to metal fabrication, choosing the right painting method is crucial for durability and aesthetics. At Armes Precision, we excel in delivering high-quality, custom solutions for various industries. From machining to precision welding, our experienced team is committed to meeting your exact specifications with exceptional results.

Are you looking for a reliable and skilled company to finish your metal fabrication project? Contact us today to request a quote and learn how we can help bring your vision to life.