Choosing the right conveyor components is a critical decision that can significantly impact your operation’s efficiency and reliability. Conveyor systems may seem straightforward, but they are complex machines with numerous moving parts that have to work together reliably with minimal downtime. This makes it challenging for conveyor builders and operators to find the right manufacturer for these components.

Different Types of Components

Conveyor systems are more than just belts and motors. They consist of various parts, each vital in ensuring smooth operation. Here are some key components you should be aware of:

- Idlers: Essential for supporting the conveyor belt and reducing friction; includes carrying, return, and impact idlers.

- Pulleys: Drive pulleys provide the primary driving force for the belt, while tail pulleys redirect the belt’s direction.

- Bearings: Support rotating parts like pulleys and idlers, ensuring smooth motion with minimal friction.

- Belt Cleaners: Remove residual material from the belt’s surface to prevent operational issues or damage.

- Conveyor Belts: Available in materials like rubber, PVC, and metal mesh; chosen based on load capacity, temperature resistance, and material being transported.

- Motors and Drives: Provide power and control speed/torque for moving the conveyor belt efficiently.

- Safety Gates: Protect workers by providing controlled access points to different sections of the conveyor line.

- Belt Scales: Measure the weight of material transported on the conveyor in real-time for process control and inventory management.

- Gravity Takeups: Maintain proper tension in the conveyor belt using a weighted pulley system to prevent slippage.

Understanding these components will give you a better grasp of what to look for when selecting parts for your conveyor system. If you have specific machining and fabrication requirements for any of your warehousing or manufacturing systems, Armes Precision is well-equipped to support your needs.

How to Understand Your Own Needs

Conveyors are not one-size-fits-all solutions. They must meet the unique demands of your operation. Here are some critical considerations to help you assess your needs:

Custom Sizing

Do you need components that fit into an existing setup, or do you require custom sizing? Standard conveyor parts may not always meet your spatial or operational constraints. Custom-sized components can ensure a perfect fit and optimal performance in your system.

Complex Routing

If your setup includes multiple turns, elevation changes, or varying speeds, you’ll need specialized components designed to handle these complexities without compromising efficiency or safety.

Heavy Load Capacity

Are you transporting heavy loads? Understanding the weight capacity requirements is crucial for selecting suitable materials and components. Heavy-duty belts, reinforced idlers, and robust motors are essential for handling substantial loads without failure.

Material Type

Different materials have different handling requirements. For example:

- Abrasive materials: Require wear-resistant belts and idlers.

- Fragile items: Need gentle handling mechanisms like cushioned belts.

- Hazardous materials: May require specialized containment features and safety measures.

Environmental Conditions

Consider the environmental conditions where the conveyor will operate. Factors like temperature, humidity, exposure to chemicals, and outdoor vs. indoor use can significantly impact the choice of materials and design features.

Speed Requirements

Conveyor systems must move at a pace that matches your production line’s speed without causing bottlenecks or overloading any part of the system. Ensure that motors and drives can maintain consistent speeds under varying loads.

Maintenance Accessibility

How accessible is the conveyor system for maintenance? Easy access to critical components can reduce downtime and maintenance costs. Consider designs that allow for quick replacements and routine checks.

Integration with Existing Systems

Will the new components integrate seamlessly with existing systems? Compatibility with current equipment ensures a smoother transition and reduces the risk of operational disruptions.

Future Scalability

Think about future scalability. As your business grows, your conveyor system should be able to expand or adapt to new requirements without significant overhauls. Plan for scalability in terms of both physical space and component flexibility.

Armes Precision specializes in providing tailored solutions that meet unique needs across various industries. Whether you’re dealing with industrial automation challenges or looking for specific conveyor systems parts, our expertise ensures you get precisely what you need.

Durability and Reliability

When investing in conveyor components, durability and reliability are paramount. These factors impact your system’s uptime, maintenance costs, and overall return on investment (ROI). Here’s what you need to consider:

- Downtime and Productivity: Reliable components ensure minimal interruptions, translating to higher productivity and fewer delays.

- Material Quality: Choose materials like stainless steel for corrosion resistance, rubber or PVC belts for general use, and specialty alloys for high-temperature environments.

- Maintenance Intervals: Durable parts reduce the frequency of maintenance tasks, cutting down on labor costs and downtime.

- Return on Investment (ROI): High-quality components may have a higher upfront cost but offer long-term savings through reduced replacements and repairs.

- Load-Bearing Capacity: Ensure components can handle your maximum load requirements to prevent premature wear or failure.

- Environmental Resistance: Opt for temperature-resistant materials, corrosion-resistant coatings, and UV-resistant plastics based on operational conditions.

- Consistent Performance: Parts should maintain efficiency and accuracy over time with precision engineering and robust design.

- Manufacturer’s Reputation: Look for manufacturers with ISO 9001:2015 and AS9100D certifications and positive customer reviews for quality assurance.

Understanding these factors helps you make informed decisions about the durability and reliability of conveyor components. Armes Precision takes pride in offering complex assembly services prioritizing quality and longevity, ensuring our clients receive dependable solutions tailored to their unique needs.

How to Choose a Manufacturer for Your Components

Selecting the right manufacturer for your conveyor components is crucial. The right partner can mean the difference between efficient operations and constant headaches. Here’s a guide to help you make an informed decision:

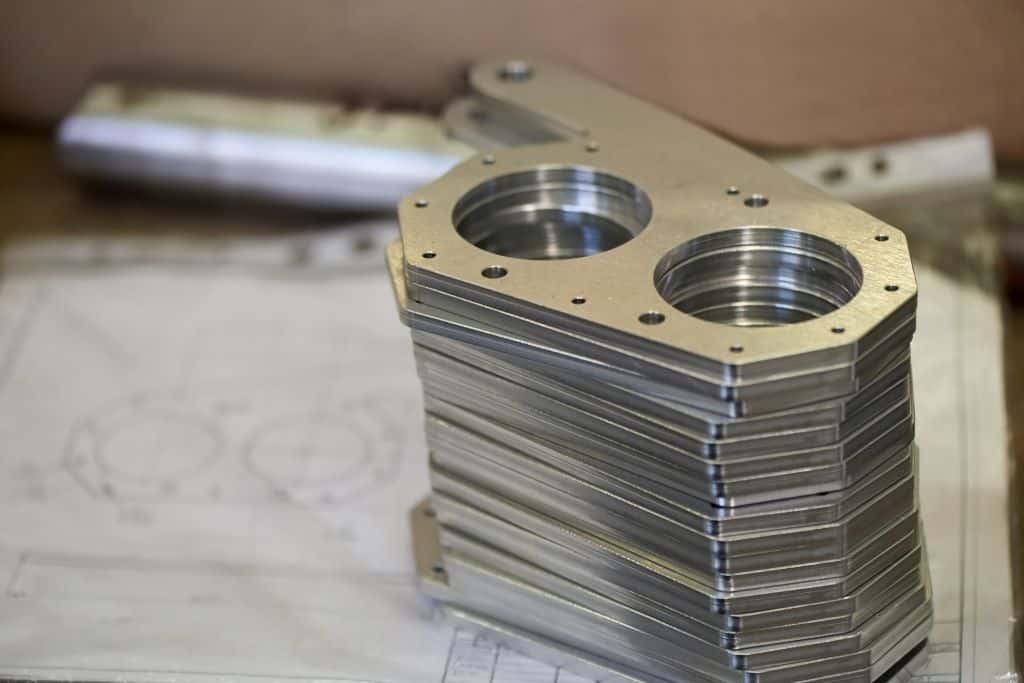

Material Compatibility and Specialties

Different applications need different materials. Ensure the manufacturer offers a range of options. Metals like stainless steel, aluminum, and titanium provide strength and durability. Plastics and composites are lightweight and corrosion-resistant. Specialty alloys like Inconel, Monel, and Hastelloy handle extreme conditions.

Versatility and Tooling Capabilities

A versatile manufacturer can manage projects of varying complexity and scale. Look for CNC machining for high-precision parts, laser cutting for detailed designs, precision welding for solid joints, and custom tools for specialized needs.

Experience and Expertise

Experience matters. A manufacturer with years in your industry understands your challenges. Look for expertise in sectors like industrial automation, utilities, or aerospace. A proven track record shows reliability and quality. Look for certifications like ISO 9001:2015 and AS9100D. These indicate robust quality management systems.

Quick Turnaround Times

Time is money. A manufacturer that offers quick turnaround times can keep your projects on schedule. Efficient quoting processes provide rapid responses to RFQs (Request for Quotes).

Customer Service

Exceptional customer service sets great manufacturers apart from good ones, so look for timely updates throughout the project lifecycle. A problem-solving approach helps overcome challenges and allows adjustments as needed.

Cost-Efficiency

Cost matters but should not compromise quality. Transparent pricing models help you understand costs and focus on long-term value over upfront savings.

By focusing on these factors when choosing a manufacturer, you can ensure you get high-quality parts tailored to your needs.

Components You Can Trust

Choosing the right conveyor components maker is a decision that can significantly impact your operation’s efficiency and reliability. Armes Precision excels in these areas, offering top-notch industrial automation solutions with unparalleled expertise. For dependable and customized conveyor components, send an RFQ today.