Getting a product from concept to completion efficiently allows companies to respond quickly to market changes. Yet, relying on multiple suppliers for machining, fabrication, and finishing often leads to delays, miscommunication, and increased costs. When various vendors are involved, the risk of supply chain disruption rises, impacting quality and timelines.

That’s where Armes Precision steps in. By offering every step of the process under one roof, we simplify your supply chain, reduce complexities, and speed up production. Below, we’ll explore how our comprehensive services make this possible—leading to smoother operations and superior results.

Why Supply-Chain Simplicity Matters

A streamlined supply chain isn’t just convenient—it’s essential for ensuring consistency, quality, and the ability to meet tight deadlines. When you rely on multiple suppliers for different phases like machining, welding, and assembly, dependencies multiply, and every additional handoff introduces more chances for something to go wrong. Each vendor operates on its own schedule and priorities. These ripple effects can extend lead times, increase costs, and compromise quality.

On the other hand, opting for a simple, direct supply chain gives you more control over every step of production. With one partner handling everything under one roof, it’s easier to spot potential issues early on and solve them proactively. This leads to smoother operations and faster turnaround times overall. Some key benefits include:

- Improved communication: Fewer points of contact simplify coordination and accelerate decision-making.

- Reduced lead times: Consolidating services allows different phases to transition more fluidly.

- Cost savings: Less back-and-forth between suppliers means lower logistical costs and fewer surprises.

- Consistent quality: A unified process ensures that all parts meet the same high standards from start to finish.

- Increased accountability: With everything handled by one partner, tracking responsibility for any issues is easier.

- Faster adjustments: Changes or revisions can be implemented more quickly since all teams are under the same roof.

- Streamlined logistics: No need to juggle shipment schedules or track multiple deliveries from different suppliers.

With a simplified supply chain, you gain efficiency and confidence.

A One-Stop Shop

At Armes Precision, we take pride in offering end-to-end metal fabrication services, covering everything from machining to complex assembly. This saves time and ensures seamless coordination across every phase of production. Our in-house capabilities eliminate the need to work with multiple suppliers, reducing the risks of miscommunications or delays. Whether you need precision machining or expert welding, we’ve got it all under one roof. Our processes include:

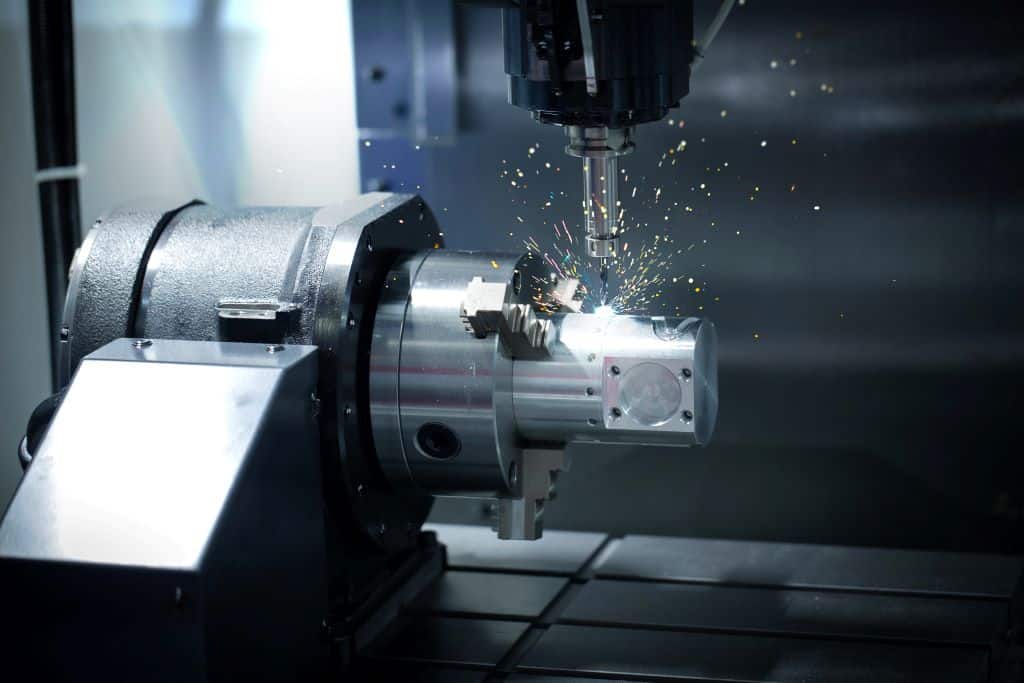

CNC Machining

Our CNC milling services ensure high precision, delivering complex parts according to your exact specifications. We work with various materials, including stainless steel, aluminum, titanium, and even fiberglass, making our CNC team highly versatile. Whether you’re working with small components or large assemblies requiring tight tolerances, we have state-of-the-art equipment and experienced machinists to get the job done right. With over 29 years of experience in machining, our reputation for precision and quality remains unmatched.

Turning Centers

Our turning centers provide exceptional accuracy and speed when creating cylindrical parts. Whether producing small-scale components or handling larger assemblies, our team delivers high-quality results. Our multiple-axis capabilities allow us to easily craft complex shapes and intricate geometries, no matter the material—be it copper, stainless steel, or titanium. The combination of modern equipment and expert machinists ensures every part is delivered on time and on spec.

Laser Cutting

When precision matters most, our laser cutting services shine. We use advanced laser technology to create clean cuts with tight tolerances while minimizing waste. Perfect for intricate designs on materials like steel or aluminum, laser cutting is ideal for industries requiring detailed work. With minimal material waste and reduced need for finishing due to the clean cuts produced, this process is efficient and cost-effective—saving time and money.

Metal Forming

Our metal forming services feature advanced press brakes that handle a wide range of shapes and sizes. We bend everything from thick steels to lighter aluminum alloys while maintaining tight tolerances and focusing on detail in every project. Whether you need simple bends or more complex shapes, we can accommodate projects of any size with speed and efficiency.

Precision Welding

For projects requiring strong joints and durable results, our precision welding services cover a range of metals including aluminum, stainless steel, and other alloys. Skilled in TIG, MIG, and oxy-acetylene welding methods, our welders combine craftsmanship with technology to create high-quality welded parts for industries such as aerospace, automotive, and medical devices. Every project receives meticulous attention to detail, ensuring a strong and visually appealing finish.

Complex Assembly

From simple sub-assemblies to intricate systems integration, our team offers professional complex assembly services tailored to your needs. Whether assembling multiple sheet metal parts or combining machined components into a finished system, we ensure consistency and precision at every step. Our quality control measures verify that everything is built to exact specifications before leaving our facility.

Why a One-Stop Solution Delivers Better Results

A one-stop solution doesn’t just streamline the supply chain—it also ensures better results. Handling every production stage under one roof provides a continuous line of communication between teams. This direct collaboration allows engineers, machinists, and welders to work closely, ensuring that each phase complements the next. Issues are identified early and addressed swiftly, preventing costly delays or rework.

Plus, with everything happening in-house, we maintain strict quality control across the board. From machining to welding to assembly, our team works together to deliver consistent quality every step of the way. This kind of integrated approach not only produces superior products but also minimizes errors and ensures faster delivery without any interruptions in workflow.

Reliable Metal Fabrication

Reliable metal fabrication requires more than just skilled hands—it demands a comprehensive approach. At Armes Precision, we offer everything from machining and fabrication to welding and assembly under one roof. This integrated process provides consistent quality, faster turnaround times, and fewer supply chain headaches. Whether you’re working on a small prototype or a large-scale project, our experienced team ensures every part is produced to exact specifications.

Looking for a reliable, experienced, and highly skilled company to finish your metal fabrication? Send an RFQ (request for a quote) today.