In today’s digital age, data centers are the backbone of our connected world. From cloud computing to streaming services, the demand for data processing and storage is surging. However, powering these data centers sustainably is a challenge. One needs to look no further than in Virginia where a new power transmission project will keep coal plants operational to meet demand. Enter nuclear energy—a reliable and low-carbon solution. As a leading machining and fabrication company, we understand the critical role our industry plays in this energy revolution.

The Growing Demand for Data Centers

Data centers have been proliferating worldwide driven by the exponential growth of internet usage. Northern Virginia in particular is the largest data center market in the world. More recently, however, datacenters are increasingly consuming more power due to the rise of AI and machine learning. Estimates predict that AI-related datacenter power consumption could reach 7.3% of total grid power by early 2025 and potentially 25% of the US’s electricity by 2030. These facilities require massive amounts of energy to operate efficiently. Traditional energy sources, like coal and natural gas, contribute significantly to carbon emissions, exacerbating climate change. Hence, the need for cleaner, more sustainable energy sources is paramount. To meet these demands, datacenters are exploring diverse energy sources, including solar, wind, nuclear, and natural gas.

Why Nuclear Energy?

Nuclear energy offers several advantages that make it an ideal power source for data centers:

- Low Carbon Emissions: Nuclear power plants produce minimal carbon emissions, helping combat climate change.

- Reliability: Unlike solar or wind, nuclear energy provides a consistent power supply, crucial for the 24/7 operation of data centers.

- Efficiency: Nuclear reactors generate a large amount of energy from a small amount of fuel, making it a highly efficient energy source.

The Environmental Impact

Switching to nuclear energy for powering data centers has a profound environmental impact:

- Reduction in Carbon Footprint: By replacing fossil fuels with nuclear power, we significantly cut down on greenhouse gas emissions.

- Conservation of Natural Resources: Nuclear energy’s high efficiency means less fuel is needed to produce the same amount of power, conserving natural resources.

- Mitigating Climate Change: As a low-carbon energy source, nuclear power plays a crucial role in global efforts to mitigate climate change.

The Role of Machining and Fabrication

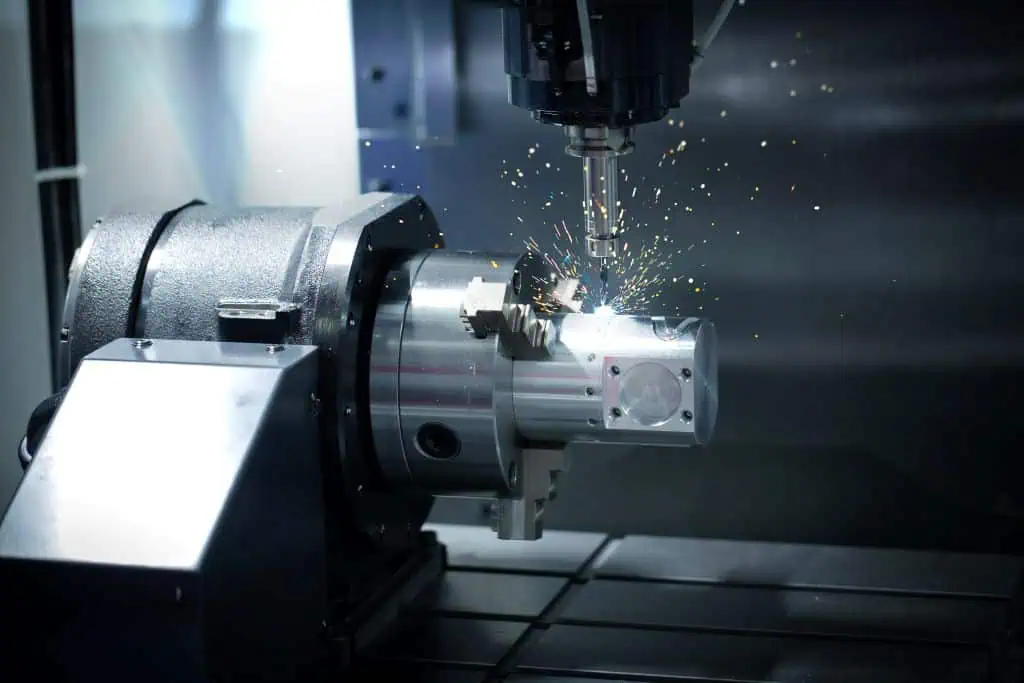

Our industry, encompassing welding, machine shops, metal forming, assembly and metal fabrication, plays a vital role in the nuclear energy sector. Here’s how:

- Construction of Nuclear Plants: The construction of nuclear power plants requires precision engineering and high-quality materials. Steel fabrications, laser cutting, and advanced welding techniques ensure the structural integrity and safety of these facilities.

- Maintenance and Upgrades: Regular maintenance and upgrades are essential for the safe operation of nuclear reactors. Our machine shop services and Virginia fabrication expertise are instrumental in providing the necessary components and repairs.

- Innovation in Fabrication: Continuous advancements in metal fabrication and machining technology allow us to create more efficient and durable parts, contributing to the longevity and reliability of nuclear power plants.

Supporting Virginia's Nuclear Future

Located in Virginia, we are proud to contribute to the state’s nuclear energy initiatives. Virginia is home to several nuclear facilities. Our local expertise in fabrication and machining supports these critical infrastructures. By providing top-notch steel fabrications and machining services, we help ensure the safe and efficient operation of Virginia’s nuclear plants.

Embracing a Sustainable Future

The shift towards nuclear energy is not just about meeting the growing power demands of data centers; it’s about embracing a sustainable future. Our machining and fabrication company is committed to supporting this transition through our expertise in areas such as:

- Laser Cutting: Precision laser cutting ensures exact dimensions and high-quality finishes for components used in nuclear reactors.

- Welding Expertise: Our welders are skilled in various welding techniques, ensuring robust and reliable joints essential for high-stress environments.

- Steel Fabrications: We specialize in custom steel fabrications tailored to meet the specific needs of nuclear power plants, from containment structures to support systems.

By doing so, we contribute to a cleaner, greener world while powering the digital revolution. For more information on our services and how we can support your nuclear energy projects, contact us today.