In the world of manufacturing, mechanical assemblies are the backbone of countless industries, from aerospace to automotive and beyond. These assemblies are much more than a collection of parts—they’re intricate systems where every component must work seamlessly together to deliver reliability, efficiency, and longevity. Precision machining plays a pivotal role in ensuring that these components fit and function as intended.

At Armes Precision, we understand the immense value that high-quality machining brings to mechanical assembly. With decades of experience and a commitment to excellence, we work closely with our clients to deliver components that exceed expectations in terms of accuracy and performance. Let’s explore how precision machining influences mechanical assemblies and why it’s vital for anyone looking to achieve long-lasting, efficient systems.

Precision Machining Explained

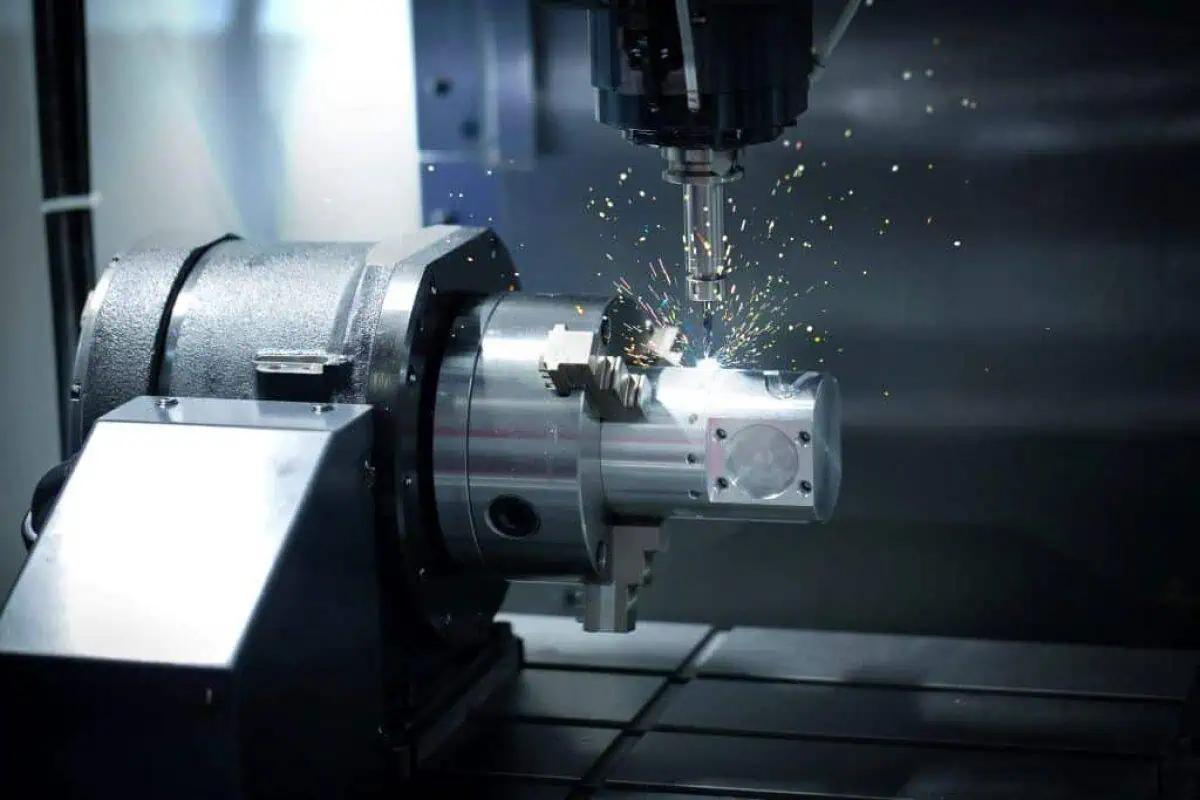

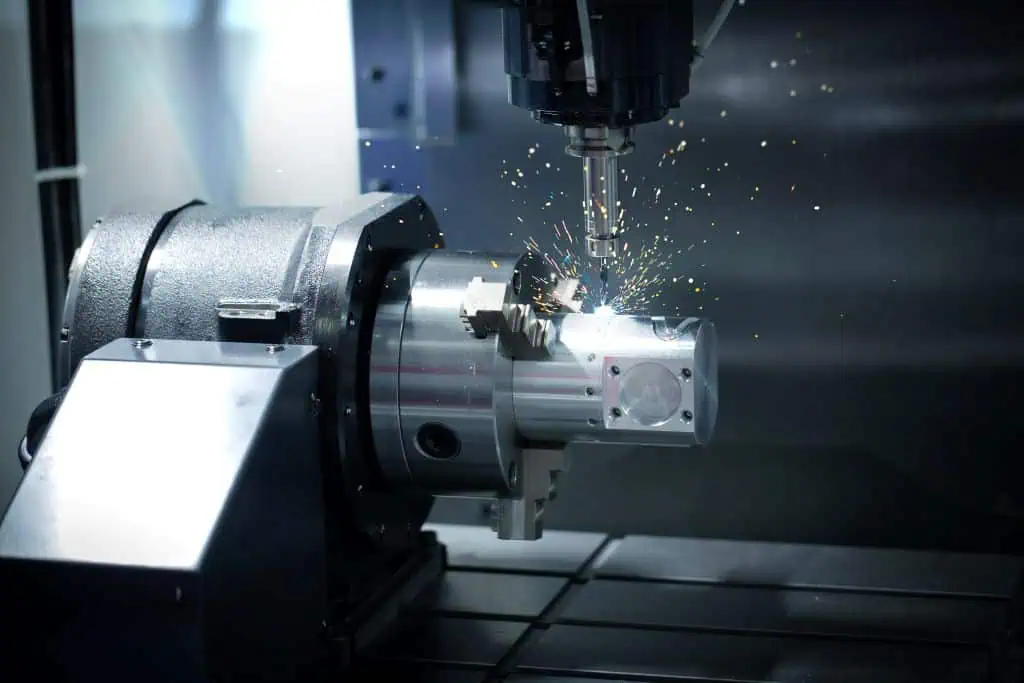

When we talk about precision machining, we refer to manufacturing techniques that produce components with extremely tight tolerances. It’s a process driven by advanced equipment such as CNC mills, lathes, grinders, and laser cutting machines, which remove material from a workpiece with unparalleled accuracy. The goal is simple but demanding: produce parts that meet exact specifications with minimal deviation.

Mechanical assembly refers to the process of joining multiple components into a cohesive structure or system. Whether assembling an engine for a jet aircraft or constructing a surgical device, the success of the assembly depends largely on how well-machined each component is. Any deviation beyond permissible tolerances can lead to misalignment, premature wear, or even system failure. That’s why precision machining is foundational for effective mechanical assemblies—it ensures that every part fits perfectly.

At Armes Precision, our facilities are equipped with state-of-the-art CNC machines capable of handling complex geometries while maintaining exact tolerances. From aluminum to Inconel to high-strength plastics, we work with a wide range of materials to meet the rigorous demands of various industries.

How Precision Machining Makes for Better Mechanical Assembly

Precision machining has a transformative impact on mechanical assemblies by improving fitment tolerance, reliability, and efficiency. These benefits cascade throughout the lifecycle of the assembly, ultimately saving time and money while enhancing system performance.

Better Fitment Tolerance

Tolerances lie at the heart of precision machining. They’re more than just numbers on a blueprint. A tolerance defines the allowable variation in a part’s dimensions while maintaining its functionality. In applications like aerospace turbines, where tolerances are often measured in microns, even the slightest deviation can impact safety or performance.

With precision machining, we achieve these tight tolerances consistently. Our advanced CNC equipment ensures parts are manufactured accurately and repeatedly, without deviations. This precision minimizes installation issues and prevents problems like misalignment or material stress during assembly.

For example, in automation systems, tight tolerances enhance operational efficiency by reducing friction and wear over time. Poorly machined components, on the other hand, can result in gaps or interference that disrupt assembly—a risk that industries like medical devices or aerospace simply cannot afford.

Better Reliability

Precision machining enhances the reliability of mechanical assemblies by delivering parts with consistent quality and smooth finishes. Accuracy ensures that components operate as intended for extended periods without frequent repairs or replacements.

Consider turbine blades in energy systems. These parts face extreme temperatures and pressures where failure isn’t an option. Precision machining minimizes stress points by creating consistent dimensions and flawless finishes, reducing the risk of cracking or fatigue.

We implement thorough quality checks at every stage—from material selection to post-machining inspection—to ensure each part meets or surpasses specifications. This dedication results in assemblies that deliver dependable performance even under demanding conditions, whether for the defense sector or cutting-edge medical devices.

Better Efficiency

Efficiency isn’t just about speed—it involves reducing energy usage, ensuring operational smoothness, and lowering maintenance demands. Precision machining directly improves efficiency by creating parts that fit perfectly and function seamlessly within their assemblies.

For instance, consider precision-machined gearbox components in automotive applications. Perfectly crafted gears enable smoother power transfer across the drivetrain, reducing energy losses and creating quieter operations. Similarly, components with reduced friction and vibration translate to lower power consumption and fewer maintenance requirements.

By minimizing wear and extending service intervals, precision machining reduces both downtime and operating costs for clients. At Armes Precision, our investment in multi-axis CNC machines and decades of experience ensure optimized efficiency across all our projects.

Improved Scalability

Precision machining isn’t just about producing one perfect part—it’s about replicating that perfection consistently across high-volume production runs. This capability is invaluable for industries like automotive or medical devices, where uniformity is essential for reliability and performance.

Advanced CNC equipment allows us to program machines for repeatable precision on every part we produce. Once the setup is complete, production becomes efficient and consistent, reducing material waste and minimizing errors even as quantities scale into the thousands or millions.

This scalability also provides cost savings and faster lead times for clients, particularly in industries where demand can rise suddenly. Whether it’s producing surgical device components or aerospace systems, precision machining enables us to meet large-scale production needs without compromising on quality.

By combining accuracy with efficiency, we ensure seamless scalability while maintaining the integrity of mechanical assemblies for projects of any size.

Reliable Mechanical Assembly Solutions

Precision machining isn’t just about creating parts—it’s about crafting solutions that improve the performance and dependability of entire systems. At Armes Precision, we combine our advanced technology with decades of craftsmanship to deliver components and assemblies that set new benchmarks for quality.

Whether you need tight-tolerance parts for medical devices or robust components for defense systems, our team has the skills and equipment needed to bring your designs to life.

We pride ourselves on providing unmatched customer service, from quick quote turnarounds to delivering projects on time and within budget. As AS9100D and ISO 9001-certified manufacturers, quality is central to everything we do.

Looking for a reliable, experienced, and highly skilled company to manufacture your products? Send an RFQ today. Together, we’ll create perfection—one component at a time.